SGS Safe Touch Pro – Vehicle Shop Edition

Integrated Control. Advanced Safety. Total Confidence.

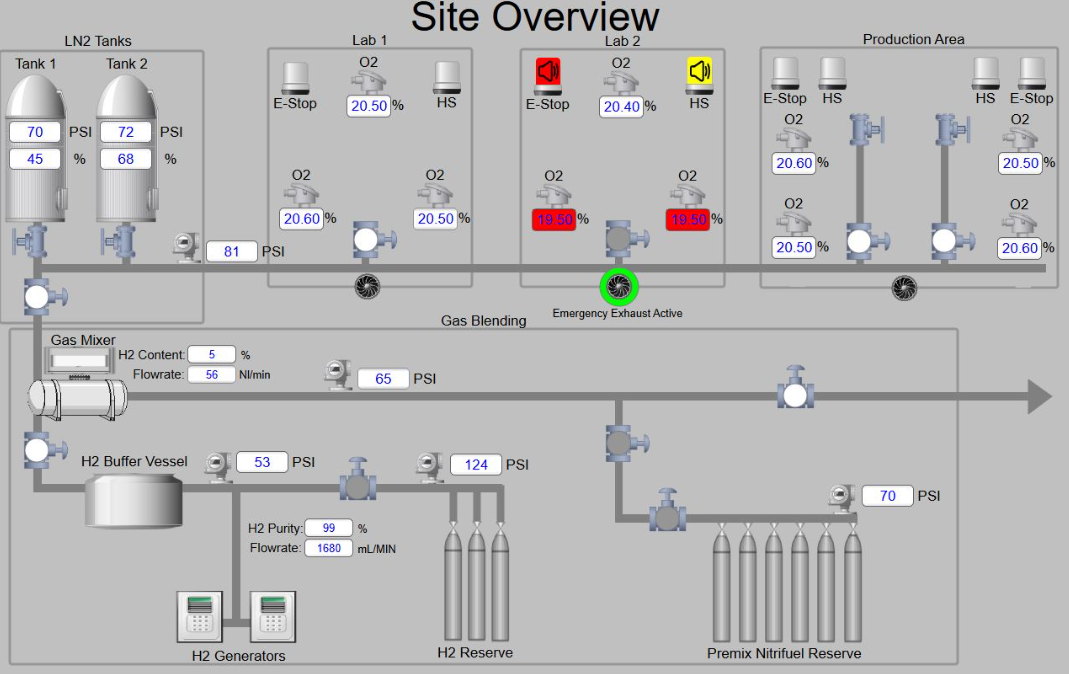

Introducing the SGS Safe Touch Pro Vehicle Shop Edition

The SGS Safe Touch Pro by Safe Gas Systems is a UL Listed, SIL-rated 12" touchscreen control panel engineered to seamlessly manage, monitor, and protect your gas delivery systems. Whether controlling bulk gas tanks or integrated facility processes, Safe Touch Pro provides total situational awareness from a single, intelligent interface.

- Exceeds NFPA 55, OSHA, IFC, CGA, and all current applicable standards and regulations

- Designed for oxygen, nitrogen, argon, helium, carbon dioxide (CO2), hydrogen, methane/natural gas, nitrous oxide, and other specialty or mixed gases – with this version specifically focused on flammable gases used in vehicle fuel applications, such as natural gas and hydrogen

- Built for critical industries: Life sciences, laboratories, research, food, aerospace, and industrial

System Features – Right Out of the Box

- Emergency Stop (E-Stop) Station Monitoring

- SSVs & Dump Valve Actuation + Position Feedback

- Exhaust Control – Process & Emergency Fan Control & Verification

- Door/Seal Interlocks, Leak Detection Inputs

- Gas Detection System Integration with Real-Time Sensor Readings & Fault Reporting

- Web-Based & Cellular Remote Access

- Alarming, Trending, and Event Logging Built-In

Seamless Integration & Communication

The Safe Touch Pro interfaces effortlessly with:

- Process Equipment – gas blenders, analyzers, chillers, pumps, vaporizers

- Facility Systems – fire alarm, building automation, emergency exhaust

- Protocols Included: ProfiSafe, ProfiNet, Profibus, Modbus

Compliance Certifications

- UL Listed Control Panel (UL 508A)

- SIL 2 Certified (IEC 61508 & ISO 13849-1)

- Meets All Relevant CGA, NFPA 55, IFC, and IBC Requirements

Full Process Control

Advanced I/O and logic modules allow for centralized control of:

- Tank Pressure, Level, Line Pressure

- Flow Rates & Temperature Monitoring

- Process Timing & Cycle Control

- Low Temp Cutoffs, Vaporizer Cycling

- Gas Blending & Blend Ratio Control

- Gas Purity Analysis & Backup Switching

Typical System Applications

Tank Farm Management

- Multiple Pressure, level, temperature, flow and leak monitoring modules

- Cryogenic tank and vaporizer cycling and supply switchover

Cryogenic System / Cryogenic Processing Room Management

- Safety Valve Actuation, exhaust system control, verification and actuation, door interlocks, process interlocks such as nozzle position verifications

- Real-time gas detection and E-Stop integration and logic resolution

Delivery System Management

- Final line pressure control, pressure drop, flow tracking, purge validation and purity monitoring

- Safety interlocks and auto-shutdown logic

Gas Generation Management

- Integration with any gas or liquid generating system

- Flow balancing, alarms, and production control

Gas Blending System Management

- Analyzer feedback, blend ratio monitoring, and automated control

- Auto-switch to premixed backup in alarm or out-of-spec

LPG / Hydrogen Vehicle Shop Safety Management

- Emergency Exhaust

- Heater Overrides/Interlocks

- Overhead Door Controls

- Gas Detection

- Notification Devices and More

Gas System Purity Management

- Continuous sampling and analyzer integration

- Low/high purity alerts, blend verification, backup switching

Why Choose SGS Safe Touch Pro?

- Built by industry experts in gas detection, cryogenics & compressed gas systems

- Modular, scalable, and field-configurable

- Engineered for the most demanding safety environments

Contact Us

Your complete safety and process control solution—engineered, integrated, and delivered by the professionals at Safe Gas Systems.

Contact us for thorough gas distribution and storage inspections that are designed to guard your company against potential malfunctions or harmful incidents.

Share this page: