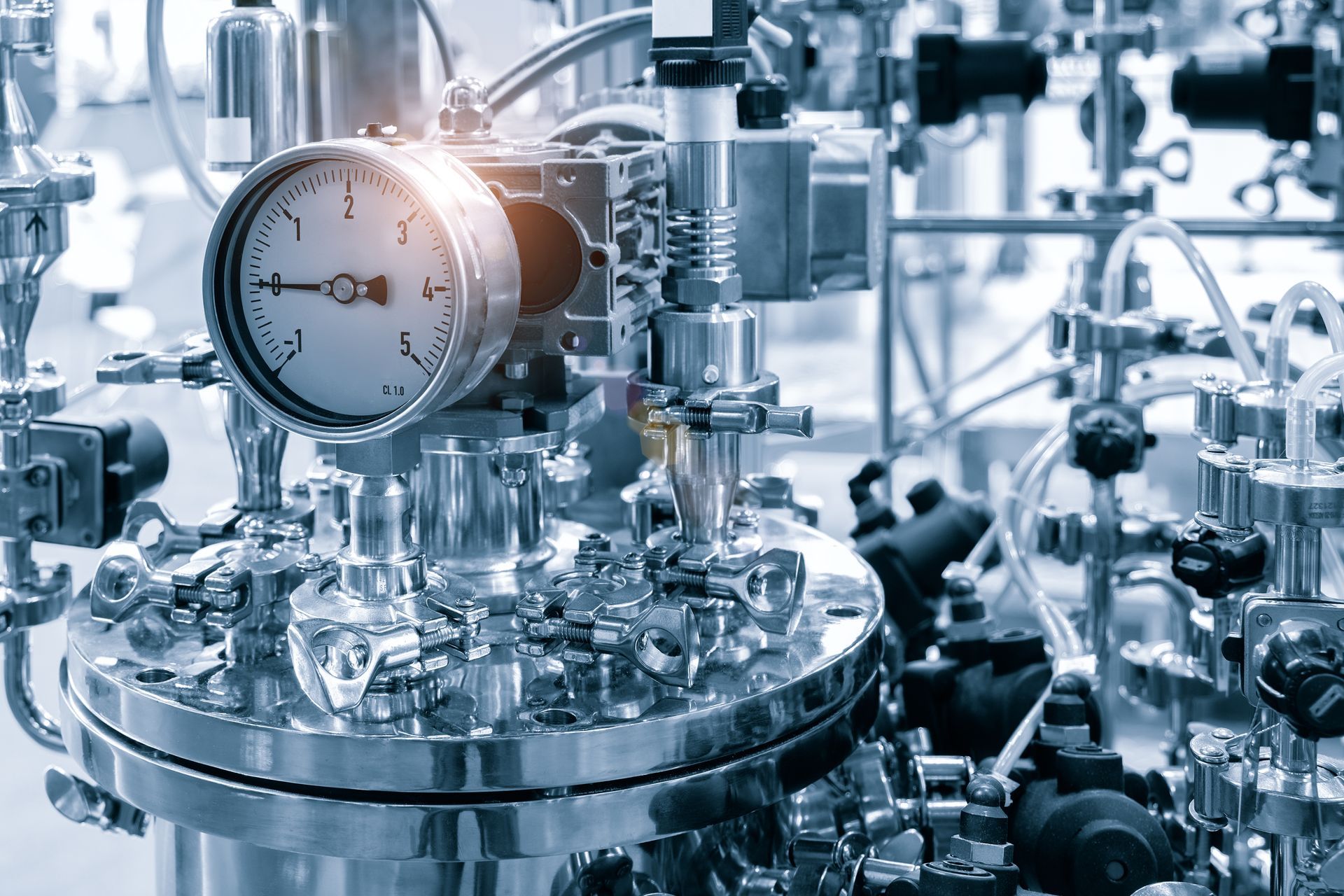

Controls for Gas & Cryogenic Systems

Introducing SGS Safe Touch Pro: Your Integrated Gas System Control Solution

Safe Gas Systems proudly introduces the SGS Safe Touch Pro, a UL Listed, SIL-rated revolutionary 12-inch touchscreen control panel designed to centralize and simplify the monitoring and management of your bulk gas systems and their associated processes. SGS Safe Touch Pro meets all current fire and building codes, exceeding compliance requirements of the new NFPA 55-26 revisions and adhering to every relevant CGA guideline in effect today.

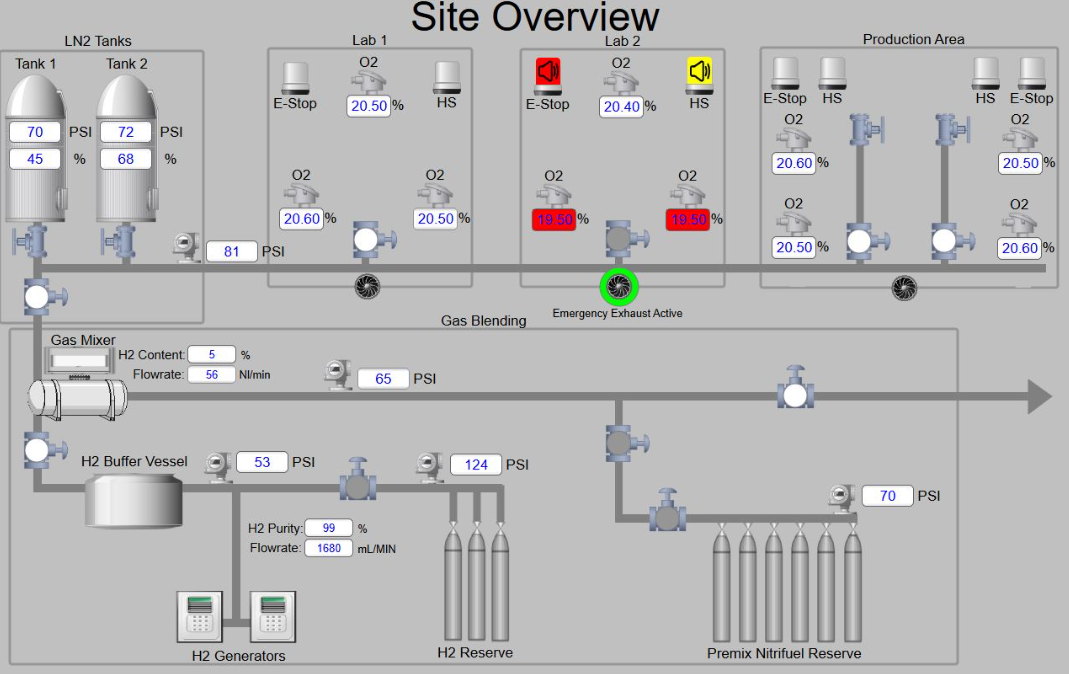

Complete Control, One Interface

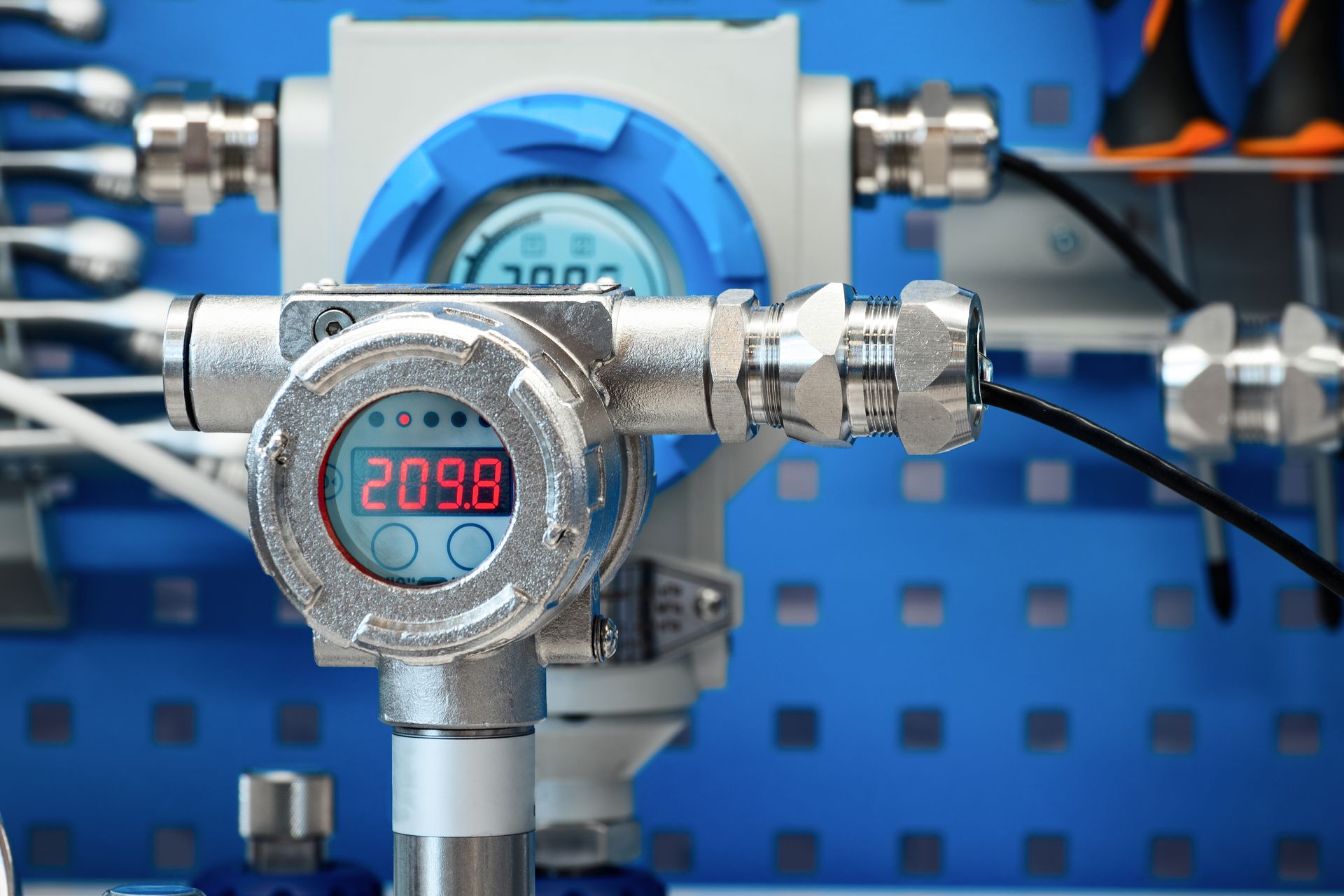

Manage every critical aspect of your gas systems from one intuitive, centralized touchscreen, significantly improving operational efficiency and safety. Effortlessly monitor and control:

- Tank Pressure and Level

- Line Pressure

- Flow Rates

- Temperature Sensors

- Gas Detection Levels

- Valve Positions

- Process Exhaust Systems

- Emergency Exhaust Protocols

Advanced Connectivity

Stay informed and maintain control from anywhere with our advanced web monitoring and cellular access capabilities. Receive instant alerts, monitor real-time data, and ensure your facility’s safety and operational integrity around the clock.

Seamless Integration with Building and Process Management Systems

SGS Safe Touch Pro is designed to integrate seamlessly with your facility’s building and process management systems. Use its powerful automation features and spare I/O capacity to monitor and control external processes and devices. Communication protocols are virtually limitless, with ProfiSafe, ProfiNet, Profibus, and Modbus included as standard options.

Complete Control, One Interface

Manage every critical aspect of your gas systems from one intuitive, centralized touchscreen, significantly improving operational efficiency and safety. Effortlessly monitor and control:

- Tank Pressure and Level

- Line Pressure

- Flow Rates

- Temperature Sensors

- Gas Detection Levels

- Valve Positions

- Process Exhaust Systems

- Emergency Exhaust Protocols

- Gas blend ratio analysis

- Gas purity/impurity analysis

Advanced Connectivity

Stay informed and maintain control from anywhere with our advanced web monitoring and cellular access capabilities. Receive instant alerts, monitor real-time data, and ensure your facility’s safety and operational integrity around the clock.

Seamless Integration with Building and Process Management Systems

SGS Safe Touch Pro is designed to integrate seamlessly with your facility’s building and process management systems. Use its powerful automation features and spare I/O capacity to monitor and control external processes and devices. Communication protocols are virtually limitless, with ProfiSafe, ProfiNet, Profibus, and Modbus included as standard options.

SIL 2 Rated Safety Systems

SGS Safe Touch Pro is available in several models featuring SIL 2 rated safety systems, offering enhanced reliability and compliance with rigorous industry safety standards. Protect your operations with certified integrity and advanced safety management.

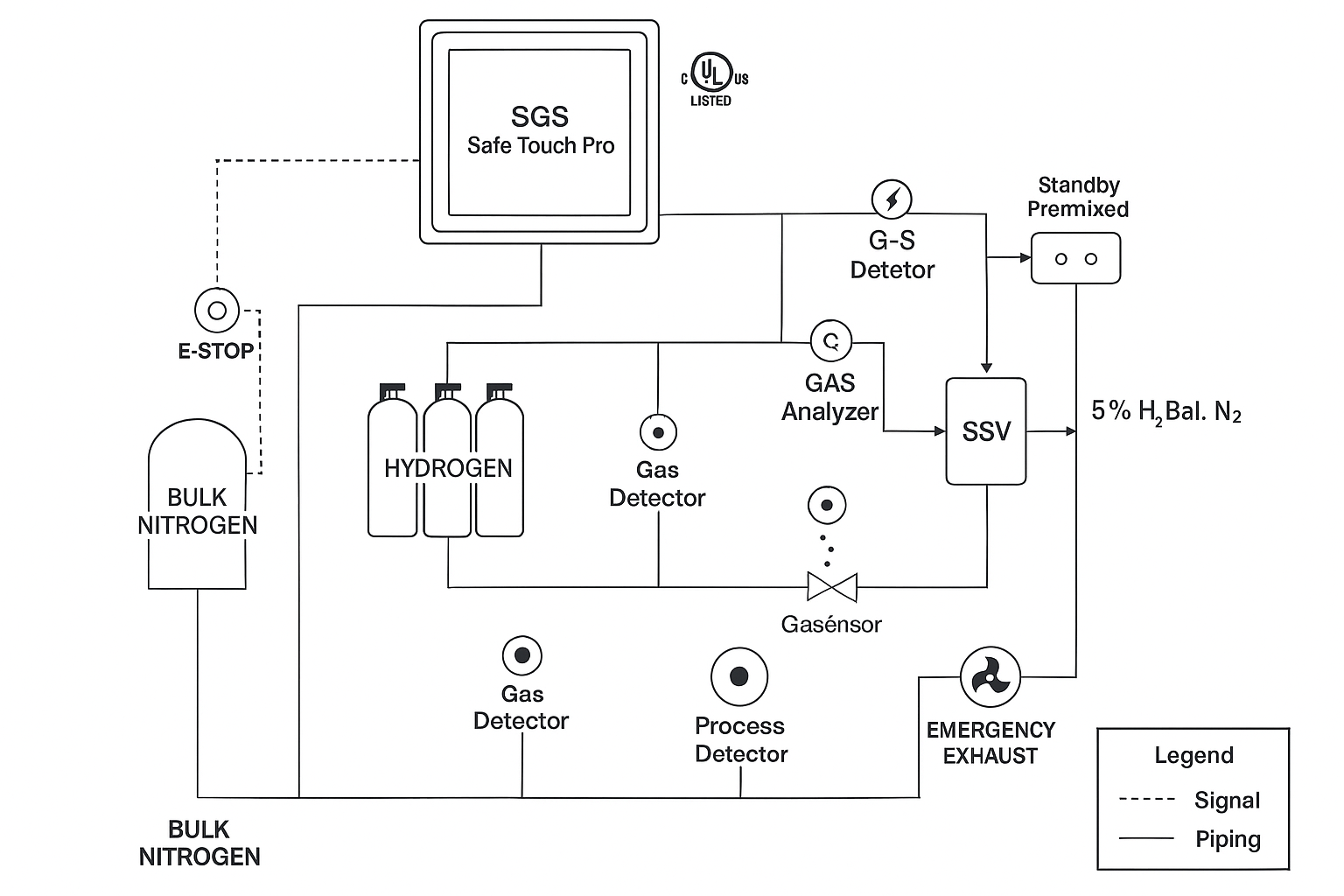

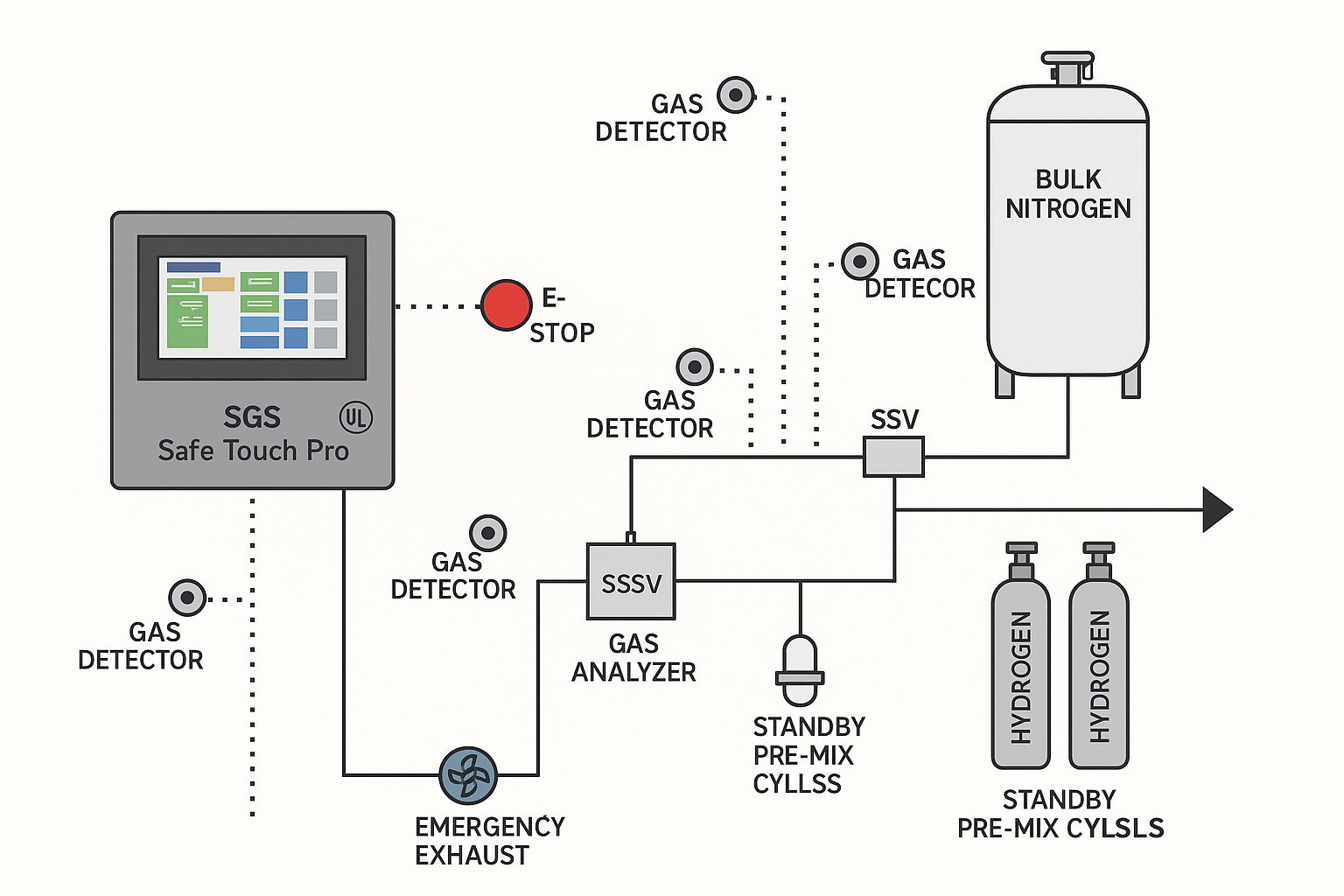

Advanced Emergency Safety Features

The SGS Safe Touch Pro includes integrated Emergency Stop (E-stop) functionality, enabling immediate and safe shutdown in emergency situations. Additionally, our specialized Safety Shutdown Valves (SSVs) ensure immediate cessation of gas or liquid flow upon gas detection alarms, such as low oxygen conditions. Emergency exhaust procedures are automatically activated and confirmed via a closed-loop verification process, ensuring total safety.

Confirmed Process Ventilation Safety

To ensure safety at all times, SGS Safe Touch Pro holds Safety Shutdown Valves (SSVs) in a closed position until the process ventilation system is confirmed operational and flowing at the specified rate. This closed-loop confirmation significantly enhances the safety of your operational environment.

Certified for Compliance and Safety

SGS Safe Touch Pro is UL Listed and meets the rigorous safety requirements of ISO 13849-1 and IEC 61508. These internationally recognized certifications demonstrate the panel’s reliability and safety in critical control applications.

Streamlined Efficiency, Enhanced Safety

Reduce complexity, minimize downtime, and ensure compliance through a seamlessly integrated control solution designed specifically for your gas system requirements. SGS Safe Touch Pro places unprecedented control and peace of mind right at your fingertips.

SGS Safe Touch Pro: Integrated Control. Advanced Safety. Total Confidence.

Safety Features Standard — Right Out of the Box

SGS Safe Touch Pro comes fully equipped off the shelf with all major safety-critical functions and logic resolution pre-integrated in a SIL-rated, UL listed panel. These include:

- Emergency Stop (E-stop) station monitoring and logic resolution

- Control, actuation, and position monitoring of Safety Shutdown Valves (SSVs)

- Control, actuation, and position monitoring of dump valves

- Verification and control of process exhaust airflow

- Verification and control of emergency exhaust airflow

- Real-time gas detection system monitoring with individual sensor readings

- Fault detection and reporting for all gas sensors

- Inputs/interlocks for door or port seal closure verification

- Leak detection monitoring

Full Process Integration

SGS Safe Touch Pro provides extensive I/O and programmable logic functionality for seamless integration with process-specific equipment and operations. Standard features now include advanced capabilities for gas blending and purity management, alongside core system controls:

- Temperature monitoring and control

- Tank pressure and level monitoring

- Line pressure control

- Flow rate tracking

- Process cycle timing and control

- Low-temperature cutoffs

- Vaporizer cycling and control

- Gas blending and blend ratio control

- Gas blend monitoring and traceability

- Automatic gas purity analysis and regulation

- And a full suite of custom logic options to suit any advanced application

SIL 2 Rated Safety Systems

SGS Safe Touch Pro is available in several models featuring SIL 2 rated safety systems, offering enhanced reliability and compliance with rigorous industry safety standards. Protect your operations with certified integrity and advanced safety management.

Certified for Compliance and Safety

SGS Safe Touch Pro is UL Listed and meets the rigorous safety requirements of ISO 13849-1 and IEC 61508. These internationally recognized certifications demonstrate the panel’s reliability and safety in critical control applications.

Streamlined Efficiency, Enhanced Safety

Reduce complexity, minimize downtime, and ensure compliance through a seamlessly integrated control solution designed specifically for your gas system requirements. SGS Safe Touch Pro places unprecedented control and peace of mind right at your fingertips.

SGS Safe Touch Pro: Integrated Control. Advanced Safety. Total Confidence.

The N2 Pedaler

Revolutionizing Liquid Nitrogen Safety and Efficiency

Safety First

No More Unattended Spills, Distracted Operators or ODH Risks

- Foot pedal activation: LN2 only flows when attended-no accidental overfills or forgotten open valves.

- Triple-redundant valve system: Flow stops instantly if the operator steps away.

- Hands-free operation: Both hands stabilize the dewar for maximum control.

- Reduces risk: Prevents frostbite, splashes, and oxygen deficiency hazards (ODH).

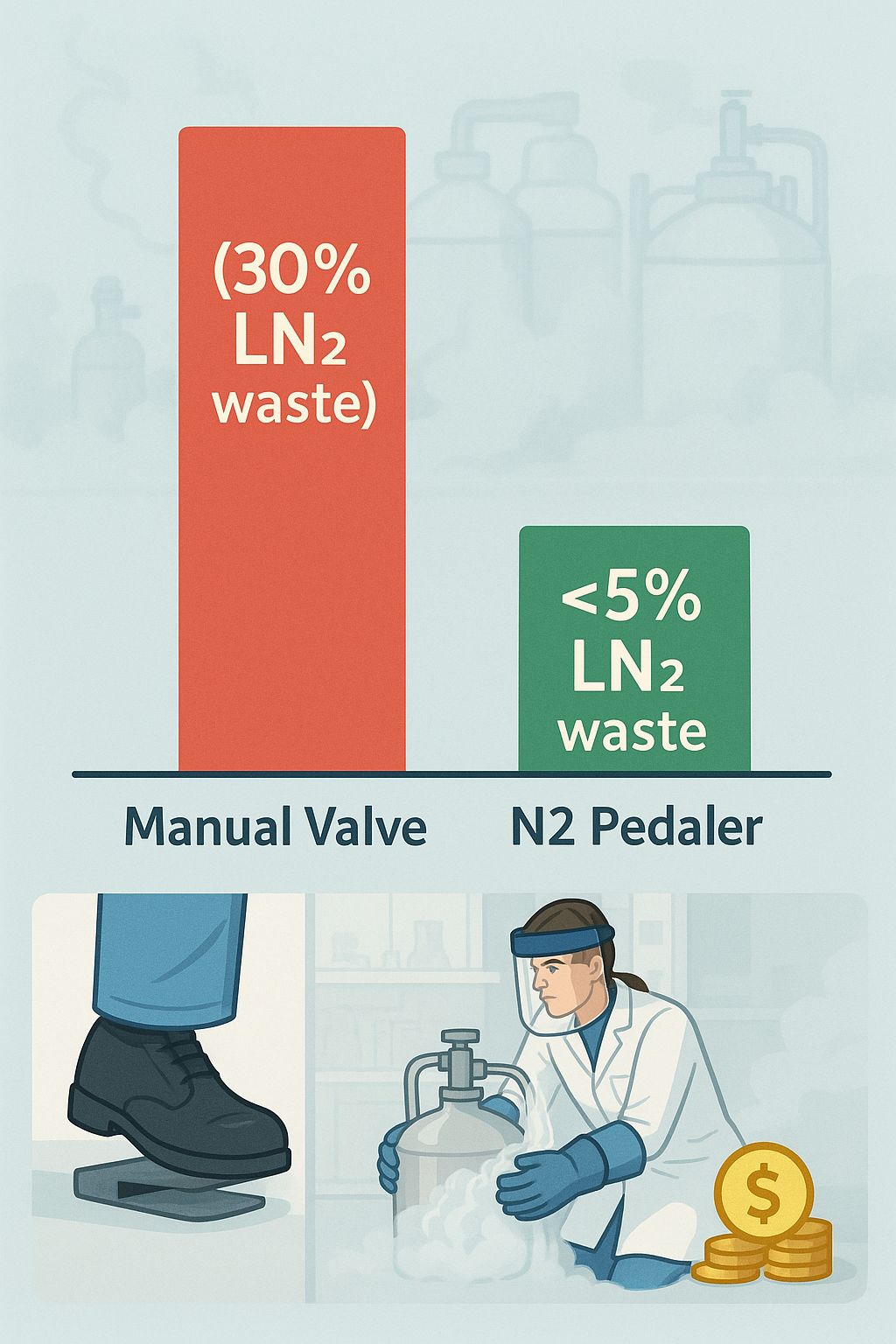

Convenience & Cost Savings

Work Smarter, Waste Less

- Intuitive, hands-free operation: Faster, safer fills with less operator fatigue.

- Easy integration: Works with standard LN2 sources-bulk tanks or local dewars.

- Precision shutoff: Minimizes LN2 waste-less than 5% loss vs. up to 30% with manual systems.

- Save money: Lower LN2 costs and eliminate spill cleanup.

Built for Compliance, Ready for the Future

NFPA 55 Compliance Made Easy

- Meets and exceeds NFPA 55: Continuous operator attendance and redundant safety systems.

- Simplifies audits: Automated logs and clear controls.

- Future-ready: Designed for upcoming code revisions-peace of mind for your facility.

Contact us for a demo or to learn how the N2 Pedaler can make your LN2 handling safer, easier, and more cost-effective.

SGS Safe Touch Pro – Blending Edition

Comprehensive Control for Gas Blending and Purity Monitoring.

Key Features

- Real-time analyzer feedback and blend ratio control

- Automated switchover to premixed gas if blend is out of spec

- Pressure, flow, and temperature monitoring at blending points

- Purity sampling and alarm thresholds

- Emergency exhaust and E-Stop logic for flammable environments

SGS Safe Touch Pro – GarageSafe Edition

Safety Automation for Vehicle Maintenance Shops Handling CNG and Hydrogen.

Key Features

- Emergency exhaust and rooftop fan controls

- OH door interlocks and purge timers

- Ceiling-mounted gas detection sensors

- E-Stop logic integration

- Heater overrides and shutdowns

Contact us for thorough gas distribution and storage inspections that are designed to guard your company against potential malfunctions or harmful incidents.

Share this page: